Barcoding & Warehousing Help and User Guide

Barcoding & Warehousing Help and User Guide will take you through the features and settings for the Sicon Barcoding & Warehousing module for Sage 200.

Search the page by pressing Ctrl + F (windows) or CMD +F (Mac) on your keyboard.

Back to all user guidesProduct overview

Help and User Guide maintained for Barcoding & Warehousing v221.0.48 and Upwards

The barcoding and warehousing solution is designed specifically for integration with Sage 200 and for the requirements of the typical Sage 200 client.

Integration with Sage 200 and the Sicon modules is in real time, with the handheld devices communicating directly with Sage 200 using Web API technology. This means there are no external databases to setup and maintain, and no data to synchronise or go out of synchronisation.

Based on an Android operating system interface, Sicon have provided all the standard functionality required in a typical Sage 200 customer warehouse in an intuitive, highly functional interface.

Being Android based you can use this application on very cheap Android based devices from phones to larger tablets, or choose a more expensive ruggedised devices with built in 1d or 2d barcode scanners, cameras, trigger grips etc.

With a high level of functionality across the Sage 200 and Sicon modules, and a great range of devices available to choose from, this solution will appeal to a very broad range of client requirements.

Note: The solution does not include the wireless network infrastructure or the hardware devices. These are up to each client to decide what they need and how best to implement it. We are happy to offer advice and recommendations where it is required. This document goes some way to suggesting some suitable options.

Why use a barcoding solution in your warehouse?

Here are the general benefits:

- Quicker and more accurate stock picking, resulting in fewer returns.

- Quicker and more accurate stock receipting, resulting in better stock accuracy.

- Real-time stock updates into Sage 200.

- Full integration with Sage 200 stock take for quick and accurate stock take, with no manual update of counts.

1. Pre-Requisites

1.1. Barcoding & Warehousing Pre-Requisites

What will I need installed to make this work?

- Sage 200 installed with the Sage 200 Commercial modules.

- The Sicon Web API installed, (this is the same Web API required for Service Manager Mobile and Task & Contact Manager Mobile). NB: this will require a single Sage 200 Web User only license regardless of the number of handheld devices.

- The Sicon Barcoding App installed on the tablet.

- The Sage 200 add-on from Sicon for Barcoding & Warehousing.

- Your choice of tablet and printer hardware.

- Minimum Android Version 5.0

- A wireless network to cover the required area.

What do I need to get this operational?

- You can use the tablet application immediately once you have everything installed even if you don’t have any barcodes on any of your products. It will give you real time updates directly into Sage 200 for each of the actions processed on the device. Barcoding your products will improve accuracy and speed of processing.

- If you have barcodes for your products these can be imported into the Sage 200 standard barcode field. If you don’t have specific barcodes for each product, our solution will simply use your stock item code instead. The supplied label layouts will look for barcode numbers in the barcode field, but if these are not available it will replace it with a barcode matching the stock item code.

- You can import a list of bin locations for your warehouse and print barcode labels for each one. Chose a label size to fit your bin sizes from the extensive range available from Zebra or other label printer manufacturers.

- If your products come in with supplier barcodes, then you can link these barcodes to your own stock items as you go. Alternatively, you can print your own barcode labels as you process each goods receipt or when you put away the stock items.

- You are now ready to start using the Sicon Barcoding and Warehousing solution with barcodes.

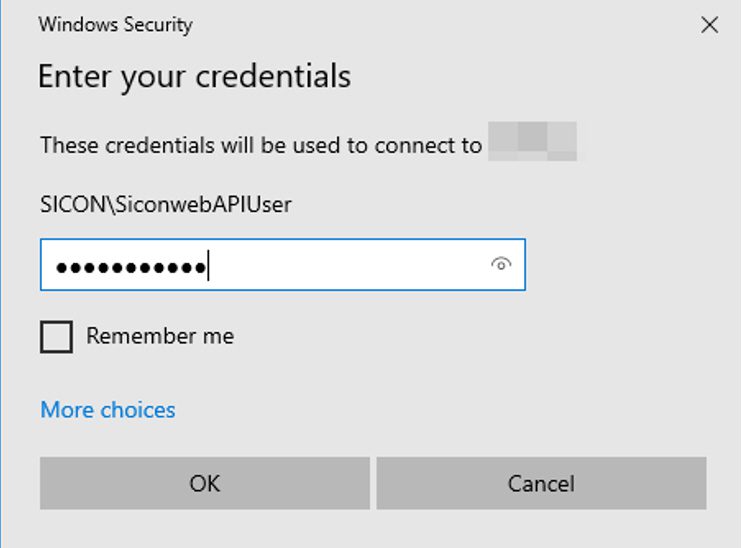

1.2. Sicon Sage 200 Web API Pre-Requisites

Requirements

- The Microsoft .NET Framework 4.5.2 must be installed on the Sage Application server.

- An appropriate Service login must be created on the domain. This is detailed in the “Create Service Account” section below.

- A Sage Web User license must be applied to the Sage instance. These must be purchased via Sage directly.

Create Service Account

Create a new Domain User that will be used to access Sage 200, such as DOMAIN\SiconWebAPI. Select the ‘password never expires’ option, and make the user a member of your Sage 200 Users Active Directory group.

![]()

Make the new user a local administrator on the server where the WebAPI will be installed.

![]()

Give the account permission to log on as a service. This can be performed under the “Local Security Policy” option found on the Active Directory server.

![]()

Open Sage System Administrator.

Right-click ‘Users’ then select ‘Update Users’ from the drop-down menu. Press OK to link the new Sage User.

![]()

Right-click on the user and choose properties, then click ‘Is Web User’, then while still on the user properties screen click the ‘Company Access’ tab and select the companies you require the WebAPI to access. The more companies accessed, the higher the memory usage of the service will be, so it is recommended to keep it to a minimum. Then Click OK.

![]()

Log into Sage as the new user. While you may not be able to access, you have to have tried to log in for the API install to be successful.

If the option to use enforced login is set in Sage system admin, then if the print services need to be restarted this will need to be temporarily disabled to allow the print services to restart (as there is no way for the system to manually enter the login credentials).

![]()

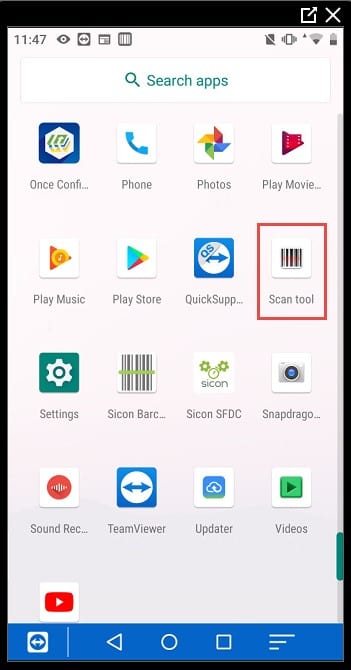

2. Downloading the Barcoding & Warehousing App

This section will take you through the stages of downloading the Sicon Barcoding & Warehousing app.

2.1. TeamViewer (Remote Access - Optional)

- Enter the Play Store

- You may be prompted to log in to a Google account if you haven’t done so already. If you don’t have one, you’ll need to create a new one. You can use the same login for all of your devices if you wish.

- Search for and install the “TeamViewer QuickSupport” app. Upon installation it may prompt to install an add-on to enable remote control, accept this:

![]()

![]()

![]()

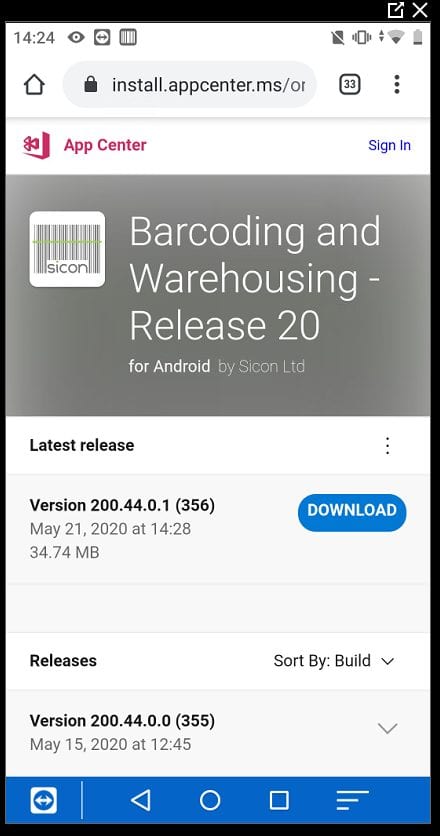

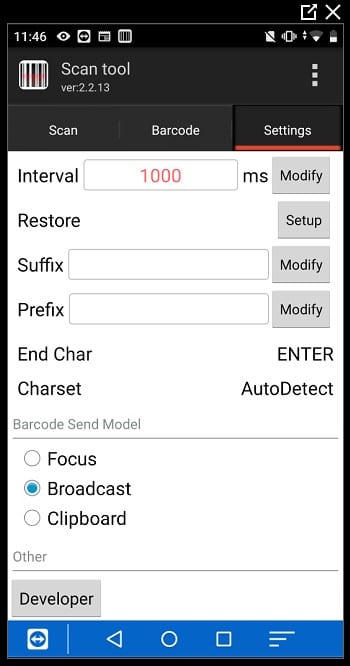

2.2. Barcoding Application

- On the Barcoding Settings screen in Sage, there is a URL field that must be provided prior to generating connection information. To populate this automatically you can navigate to the following URL “http://{Server IP/URL}/Sicon.Sage200.WebAPI/api/Location/Notify” from your mobile device, which will populate this field as well as confirm the server is accessible. Using an internal computer name will require you to be on the same network as the server and an internal ip will require you to at least be on the same vpn as the server. An external ip/name will remove this requirement.

- With the URL field populated, you can now create a QR code for the company and web API URL and physically print this out if required. This is used for populating the server details in the handheld see step 6 below.

- Create at least one user account for the app from this screen, which is required to access the application after establishing a connection. Access to the warehouses and permissions need to be set against the user. You need to give access to at least one warehouse, setting a warehouse as the default will automatically use this warehouse on login.

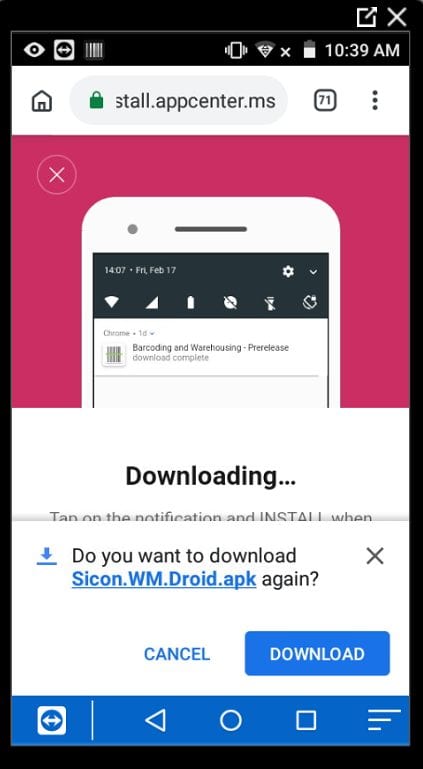

- Download and Install the Barcoding Android application on your device from the App Download web address link in Sage. Manually type in the web address for the App download in Chrome on the tablet or scan the QR code to take you to the download web page.

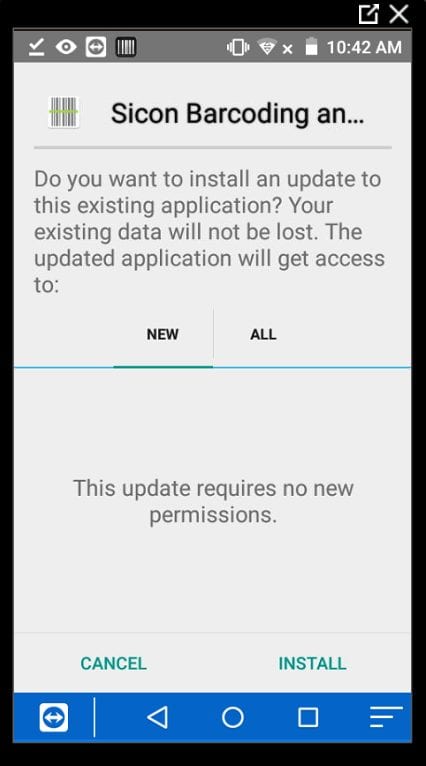

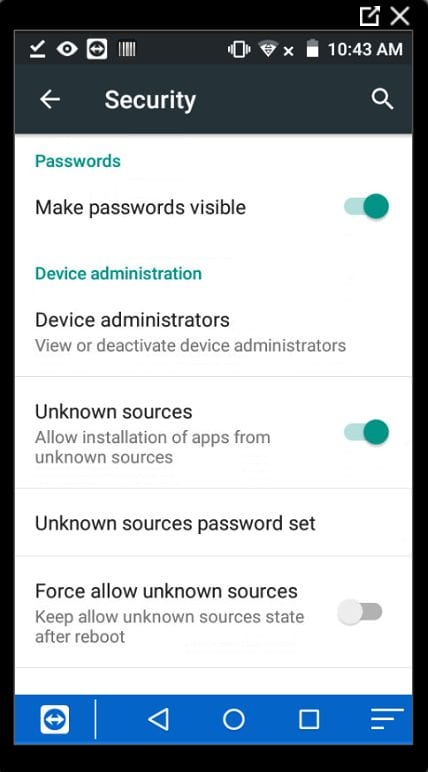

- This will require allowing installation from unknown sources, so if prompted during the installation you will need to enable it. On some devices, you’ll be prompted for a password, which by default will be “4007770876” on the Seuic devices that we recommend.

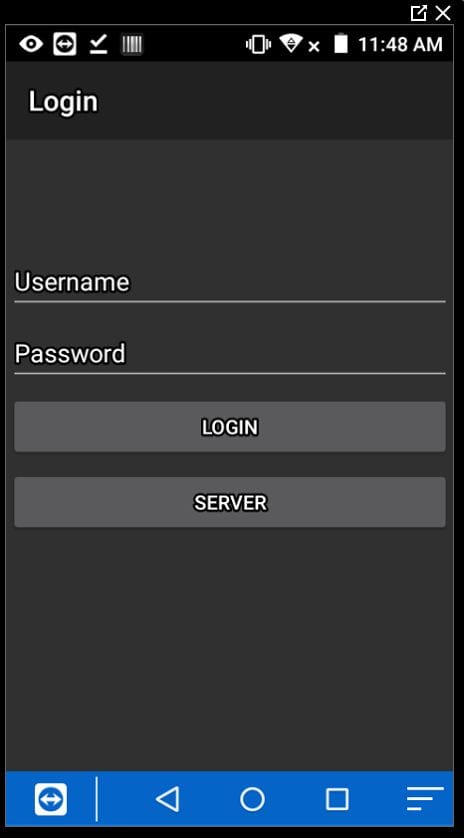

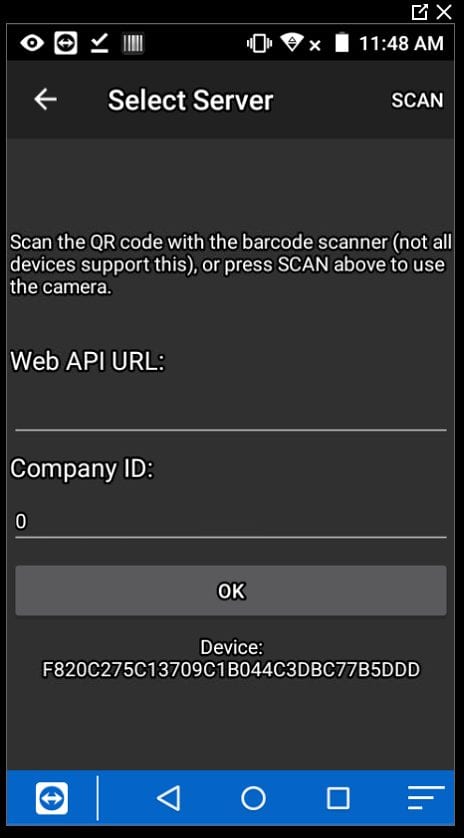

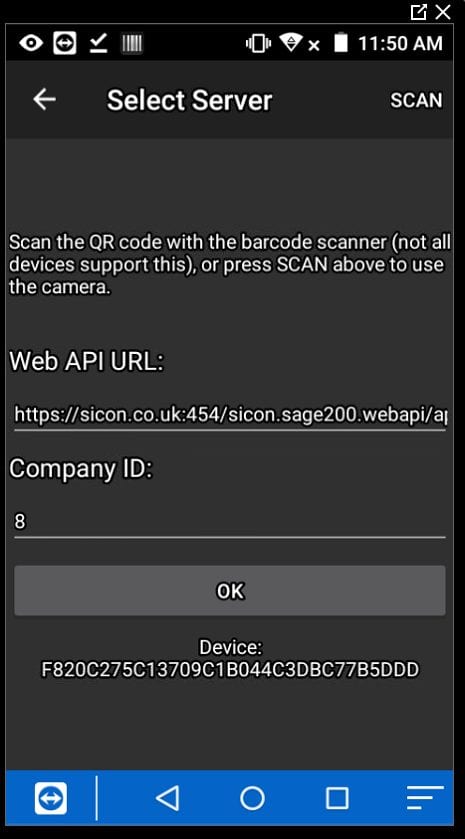

- Upon opening the app, click on server and scan the large QR code on the settings page (or printed out from step 2 above) to populate the Web API URL and company ID. Alternatively this can be entered manually if the device does not have a scanner/camera.

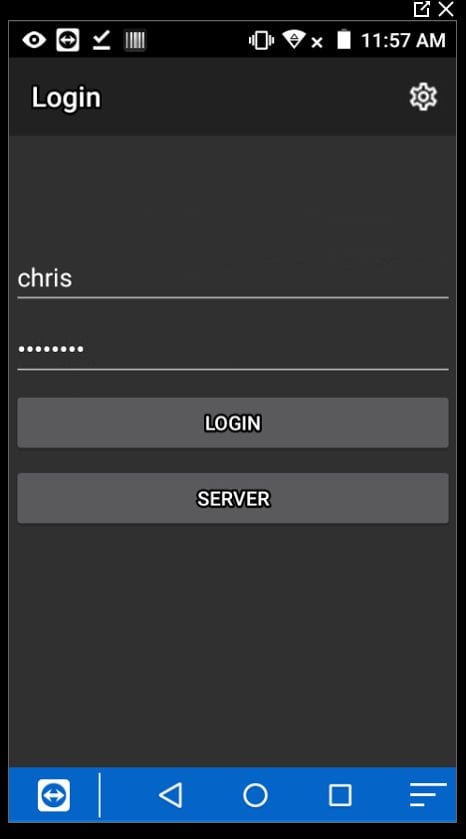

- You can then log in as the user.

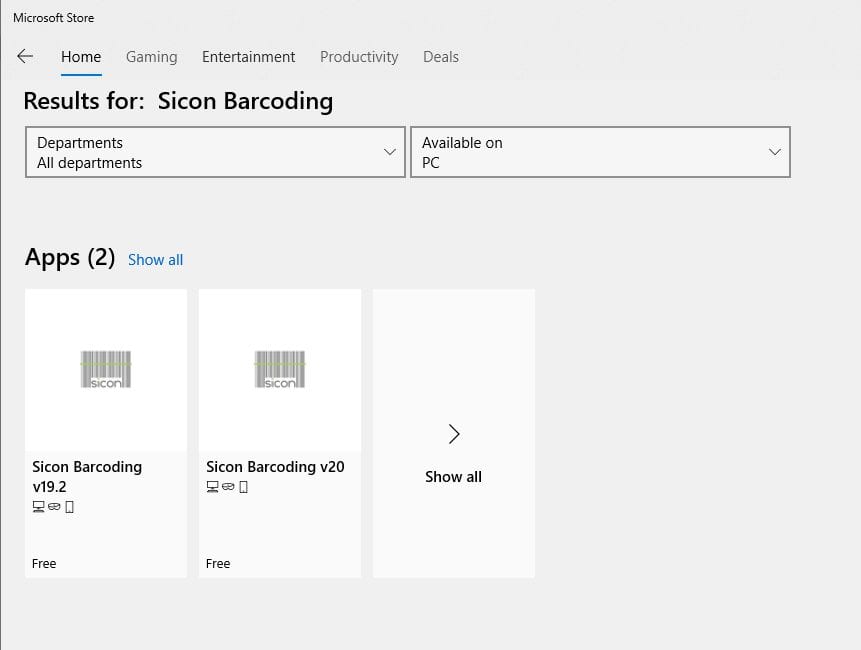

- There is also the ability to install a windows based app on to a windows 10 machine. The windows app mirrors the android app in appearance where possible, but scanning of barcodes is currently not possible. To download the windows app, go to the Microsoft store and search for Sicon barcoding.

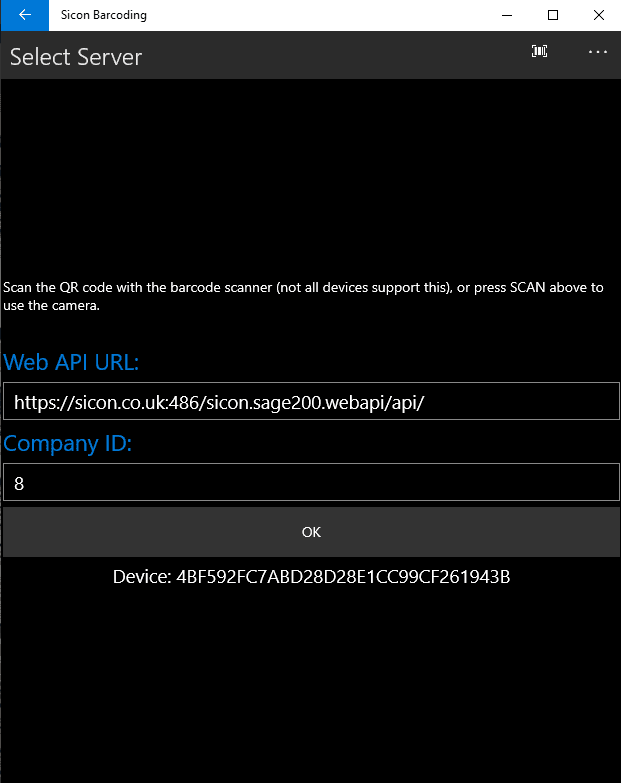

- You can then download the appropriate version on the machine and then run it. The server and company details will need to entered.

- You can the log in with a barcode user that has been set up in the Sicon barcoding settings.

![]()

![]()

3. Sage Menu

![]()

3.1. Warehouse Notifications

Stores any notifications sent from the handheld, including barcode problems, dynamic stock take results. Notifications can be cleared from the screen.

![]()

3.2. Dashboards

Dashboards can be viewed and created/amended from within this menu:

![]()

The Picking targets dashboard gives an idea of what can be achieved with a dashboard.

![]()

Each of the dashboard panels have separate panel names and are configured in the maintain dashboard panels section.

![]()

The panel can be edited and the underlying sql query viewed/amended or new queries created.

![]()

![]()

The general dashboard section provides 10 blank dashboards that can be configured.

3.3. Sales Order List

A sales order list has been included so that additional Sicon fields can be displayed on the list. The SOP ready to pick flag shows, see further details on the ready to pick flag in the SOP settings below. The pick status of the order also shows, to highlight if the sales order has been picked or packed in the handheld. This mirrors the pick status icons on the sales order list on the handheld. Where a barcode user has been assigned, this shows as does the user when a sales order is being picked in the handheld. When the order is put on a wave the wave number can also show.

![]()

The ready to pick flag can be set against multiple orders from the screen by highlighting the orders and right clicking and setting the ready to pick flag.

![]()

This can also be done from the menu item.

![]()

The Sage user requires permission to this feature.

![]()

When the Sicon courier module is also installed, the Sicon courier delivery service can be added to the Sicon barcoding SOP list. It can also be set from the screen.

![]()

3.4. Stock Transfer List

Shows a list of Sicon stock transfers, which can be accessed by highlighting a line and clicking on amend.

![]()

3.5. Stock Item Settings List

Shows a list of stock items and the barcoding settings associated with them.

![]()

The stock items can be amended from the list and also the hold pick setting amended.

![]()

3.6. Waves

![]()

Sales Order Waves can be created and amended from within these screens.

![]()

Sales orders can be found using the selection criteria or all orders can be displayed by clicking on show all orders. The orders can be added to a wave and the wave created by clicking on the save button.

When a customer is selected, an additional field to select the sales order delivery address can be used to select orders for a particular delivery address.

![]()

Existing Sales order waves can be amended from the amend sales order wave menu. The window shows the status of the wave, whether it has been assigned and if completed, when it was completed. The complete wave button allows waves to be completed. Completed waves are hidden, unless the include complete option is ticked. The Reopen wave button allows completed waves to be re-opened.

![]()

Selecting a wave and then amend wave, opens the maintain wave screen.

![]()

The wave number is added to the sales order in the pick on wave field.

![]()

On the barcoding sales order list, the wave number can also show.

![]()

Where the Sicon works order module is installed, Sicon works order waves can be created and amended. The list of works orders can be filtered on status, dates, warehouse and area.

![]()

3.7. Assign Pickers to Sales Orders

![]()

Allows sales order to be assigned to handheld users. Sales orders can be selected using a number of criteria and then assigned to a user. The handheld user will then only see orders assigned to themselves or orders that have not been assigned.

The assigned user appears on the sales order and can be added or removed individually.

![]()

3.8. Van Picks

There are a number of set up requirements for using Van picks, to enable sales orders to be picked into Vans.

In Sage accounting system manager, settings, maintain analysis codes, an analysis code for Van Numbers and Drop Number can be created.

![]()

![]()

These can then be linked to SOP analysis codes

![]()

These SOP analysis codes can then be set in SOP barcoding settings.

![]()

The SOP analysis codes can be pulled from the customer analysis code, which need to be set up.

![]()

![]()

When sales orders are entered the Van and Drop number (sequence) can then be linked to the SOP.

![]()

Enter Van Pick

In this screen sales orders can be selected and linked to a van pick. Clicking on save creates the Van wave pick.

![]()

Amend Van Pick

![]()

In this screen van picks can be amended or deleted.

When van picks are being worked on in the handheld, the status of the pick will be updated and the picks will be locked for editing/deleting.

![]()

3.9. Packaging

![]()

Packaging Enquiry

![]()

Allows enquiry on packaging records in the system, the quantity can also be edited from the edit button.

![]()

The history button can be used to see the history of the selected package item.

![]()

The delete button can be used to delete package records.

![]()

Create Package Labels

![]()

Allows packaging labels to be generated and printed.

When auto generate numbers is selected the system will use the next available number based on the packaging numbers set in the settings screen.

![]()

For example, when auto generating pallets. The system has combined the extension digit, company, prefix and serial reference followed by a system generated check digit to come up with the next SSCC pallet number.

![]()

3.10. Replenishment

Stock items to replenish can be created in this screen. Clicking on display, will show any stock item bins that are below the minimum/reorder bin level (depending on the stock transfer settings to use minimum or reorder).

![]()

When replenishing based on bin levels, the replenish quantity is the difference between the pick bin stock and the maximum. The screen shows stock items on purchase orders (on order) and on sales order (future demand), the corresponding purchase order and sales orders can be viewed from the screen by highlighting a line and clicking on view item sales order or view item purchase order.

![]()

The current quantity in the pick face bin is displayed and a link to view the stock item balances is provided. The ‘in replenish’ column will show any existing replenishments created for the stock item/bin record.

The replenish stock up to date is dictated by the setting in the barcode stock transfer settings.

This date is also used to determine what SOP allocations to move when performing the replenishment. The system will move any SOP allocated stock where the dates on the sales order fall within the replenisment requirement for days.

For example the replenish stock requirment is set for 2 days.

![]()

There are 2 allocated sales orders on the system

![]()

When processing the replenishment, the system will moved the allocations on SOP 374 to the pick face bin, as the promised for date of 26/03/2021 falls with the replenishment date.

![]()

The replenishment quantity can be manually amended if required, clicking on create, then creates a replenishment record.

![]()

![]()

The replenishment record will then appear in the handheld for processing, see the handheld features below for further details.

The created replenishment will appear in the current replenishment screen. If the replenishment has been picked and part put away, these figures will appear in this screen in the picked and replenished screen.

![]()

The bins to replenish from can be controlled by the settings in the replenishment settings, see below. When overflow or other bins are not set, then the system will replenish from bulk bins (the priority will demand on whether smart picking is enabled)

![]()

If the option to replenish future demand quantities is set, then sales order will be factored into the suggested replenishment quantity. The number of days to factor is controlled by the replenish stock requirement for days.

![]()

When creating a replenishment with the above example any sales orders with a promised for date in the next 60 days will be looked at to drive to replenishment demand.

![]()

3.11. Dynamic Stock Take

Dynamic stock takes can be created, reviewed and completed from this screen.

![]()

Clicking on view results shows, the items codes, the quantity counted and whether stock has been added or removed based on the previous quantity. It also shows the handheld user who has performed the count.

![]()

Clicking on complete, will mark the stocktake as complete

![]()

A dynamic stock take can also be created from within Sage, to count bins or stock items from a specified warehouse.

![]()

The auto select button can be used to select certain stock codes to count.

![]()

If bins that have no stock in them need to be included, then tick the include empty bins option.

3.12. Stock Shortage Transfers

![]()

In this window, you can create a stock transfer to move stock between warehouses.

![]()

Click on new transfer, add in item details and products to move and save the transfer. The transfer will appear in the handheld once the ready to pick flag has been set on the transfer. Setting the ready to pick is controlled by the settings in the barcode stock transfer settings. It can be set by printing the picking list, set when all lines allocated or manually set.

![]()

With the option to set the ready to pick flag manually, part allocated transfer can be sent to handheld for picking. Any lines that are not picked will be added to a new stock transfer.

Transfers can also be created to transfer stock to a project and then processed in the handheld.

![]()

Previous transfers can be copied by ticking the transfer required and clicking on Copy Transfer

![]()

Transfer Templates can also be created for frequently used transfers.

![]()

![]()

There is also the ability to import the transfer from a spreadsheet. Click on new transfer, then add in the to and from warehouse and despatch date. Then select the import button.

![]()

An import file can be created, saved as a csv file and then selected. The file can be checked and then imported.

![]()

This then creates the transfer lines, and the transfer can be processed as normal.

![]()

3.13. Maintenance

Maintain Zones

![]()

In this screen, Zones can be created and deleted. These zones can then be linked to bins in the maintain locations screen, see notes below.

Maintain Stores

![]()

Allows maintenance of store ID and store names for use with distribution type sales orders.

Stock Item Settings

![]()

This screen can be used to set and maintain the hold pick flag on stock items.

3.14. Maintain Locations

Within this screen, bin locations can be added/removed and sequenced and bin definitions set. The sequence dictates the order that lines will appear in the handheld for picking stock items. E.g. sales orders lines.

Where zones are being used, these can be linked to bin locations.

Bin names can be imported from the bin locations within Sage stock items using the update locations from Sage bins. Specific barcodes for the bin locations and sequences, and bin definitions can also be imported, using the Import button. The bin name, zone, barcode override and sequence can be created in excel using the template, then imported.

Bins can be exported to excel from maintain locations screen, a bin priority added and imported back. Right click on the screen and export all to excel.

![]()

Prepare the import in excel based on the template, then save as a csv file.

![]()

Then import the bins, using the import button.

![]()

You can also print bin location barcodes for use within the warehouse.

![]()

![]()

Bin locations can be flagged as a despatch bin, so in the SOP processing window, items can be moved to this bin location.

![]()

The default bin priorities can also be set in this screen, which then shows the bin type descriptions.

You can also update the existing Sage stock bin to have the new bin priority using the ‘update existing Sage bin priorities’ button. This routine also runs when an import is done.

![]()

3.15. Labels

Labels can be created from within the Sage menu labels folder.

![]()

The bin labels report, can be used to print labels for all Sage bins.

![]()

The bin labels (SiconWABlocation), can be used to print labels for any bins created in the maintain locations screen. These bins are held in a separate table namely SiconWABlocation.

![]()

The stock with bin labels, will print a label for each stock item in each bin, with a barcode for the stock item and bin.

![]()

Warehouse and Bin Labels: Can be used to print bins labels in a warehouse.

![]()

Warehouse, Bin and Stock Labels: Can be used to print a label containing a barcode for the warehouse, bin and stock code.

![]()

4. Sage Menu | Imports

![]()

4.1. Import Stock Item Barcodes

This import can be used to update the Sage stock item barcode field and/or the supplier barcodes. Create an import file in excel and save as csv format.

![]()

Select the file and click on check file, then import.

![]()

This updates the barcodes within the barcode button on the stock item and also the main stock item barcode field, if a supplier record is not specified. When the supplier code is entered, then the supplier barcode is created/updated.

![]()

4.2. Import Stock Item Settings

Allows settings on the stock items to be imported. An import file can be generated and then imported.

![]()

![]()

4.3. Import Customer Stock Codes

Allows customer barcodes to be imported against stock items using an excel import file. Create an excel CSV file using the template provided (exclude the headers when saving).

![]()

![]()

Import the file, the customer barcodes are visible against the stock item in the customer codes tab.

![]()

4.4. Import Bin Max Min Reorder Levels

This import is used to import the bin minimum, maximum and reorder levels for use with replenishment. An import file can be prepared using the example import file. The file can then be saved as a csv file and then imported.

![]()

The imported values can be seen against the bin

![]()

4.5. Import Delivery Notes

Allows records to be imported to update and despatch existing sales orders in the system. It relies on pallet information existing in the system.

For example, there is pallet of 48 boxes of avocados with pallet number 111223344000000366 in bin C-A-01

![]()

These can be picked on a sales order in the handheld.

![]()

An import file can be prepared to dictate which pallet was used for a particular sales order.

![]()

![]()

Clicking on import, updates the sales order to be despatched and records the pallet used.

![]()

4.6. Import Package Details

Allows for packaging records to be imported. An import file can be prepared based on the example import provided. This can then be imported into the system.

![]()

![]()

The imported packaging records can be viewed in the packaging information screen in Sage.

![]()

5. Sage Menu | Reports

![]()

The stocktake results by bin can be used to generate a report from a Sage stock take ordered by the bin.

The stock list by bin (export) and the stock list by bin can used to find all stock items within bins.

The packing list can be printed to show items that have been packed onto a sales order, showing the box they have been put into.

The despatched items packing list details items, will allow a packing list to be printed for despatched sales order.

The dynamic stocktake results reports can be used for displaying/printing out the results of a dynamic stock and exporting the results to excel if required.

![]()

The stock transfer detail and summary reports can be used to report on the stock transfers, showing what has been picked, despatched and received.

The stock list with barcodes can be used to report on what stock items have or do not have the Sage barcode populated.

The stock ageing by bin report relies on the following setting being set.

![]()

The report then shows the ageing of the stock, based on then when the stock was received. N.B this only works for stock items received after the setting has been enabled.

![]()

6. Utilities | Settings

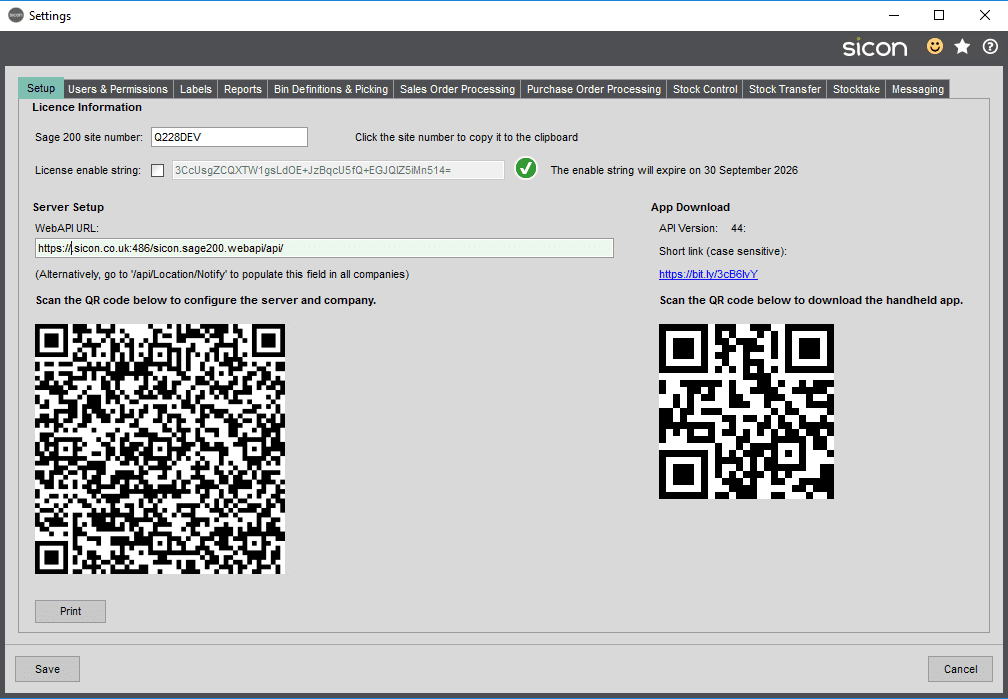

6.1. Setup

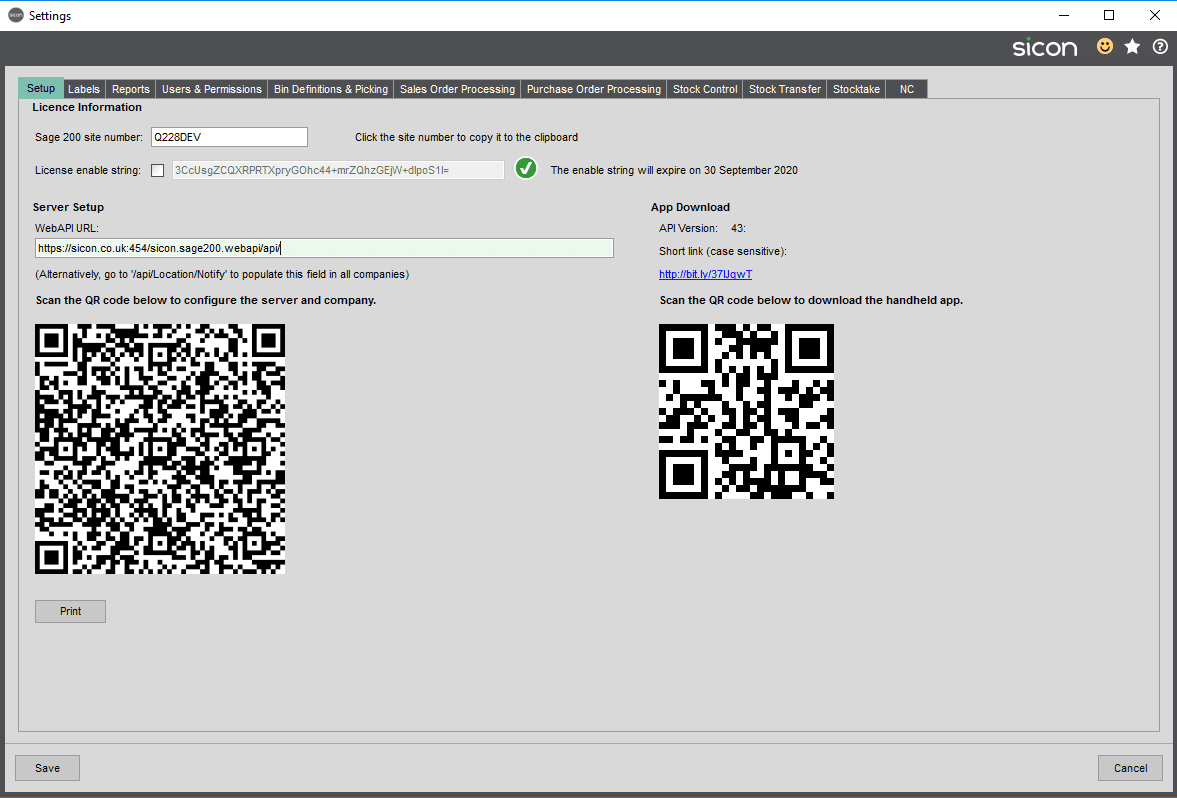

![]()

Licence enable string: Enter a Sicon enable string here to enable the module unless online enable strings are enabled.

Server Setup:

WebAPI URL: This is the Web API URL that links the handheld devices to Sage. You can navigate to the web URL (remove the /api off the URL link) You can log in to see information about the Web API.

![]()

You can populate all the database WebAPI URLs, by putting in the following Web URL in a web page followed by /api/Location/Notify. E.g. http://10.0.0.139/Sicon.Sage200.WebAPI/api/Location/Notify

![]()

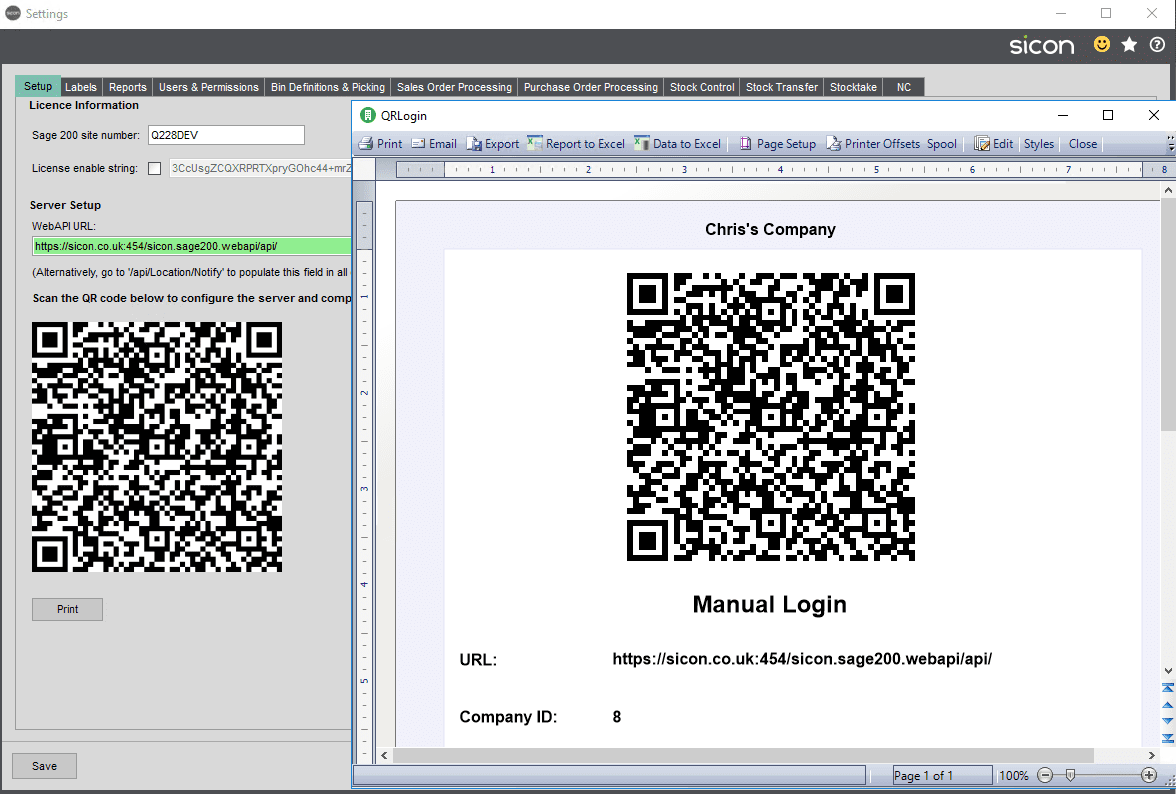

The larger QR code on the left of the screen is used for populating the WebAPI and company number in the server set up on the handheld. The code can be physically printed using the print button.

In the handheld, click on the server button and then scan the QR code to populate the Wep API URL and company number. This can be entered manually for devices that cannot scan QR codes.

![]()

![]()

App Download: Use the link on the right hand side of the screen for downloading the Sicon barcoding application onto the handheld devices. Or scan the smaller QR code on the device to open the web page to download the app.

![]()

6.2. Users and Permissions

![]()

The front screen shows each of the users set up, details of their permission and last login and logout details and the device id.

From this screen you can log users out of the app.

![]()

You can also set a time for users to be auto logged out of the device.

If the same user logs onto two different devices, the following message is shown on the handheld.

![]()

If the old login is forced out, they will then get the following message in their handheld.

![]()

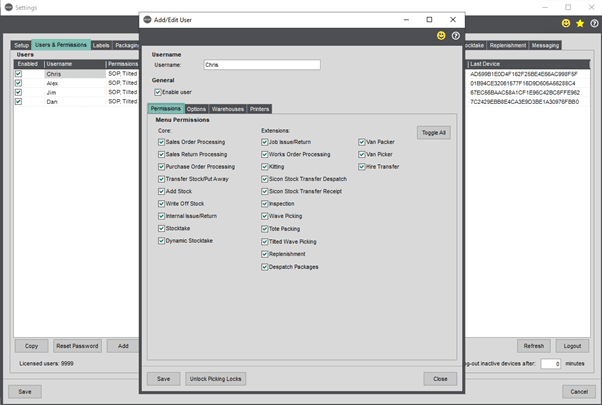

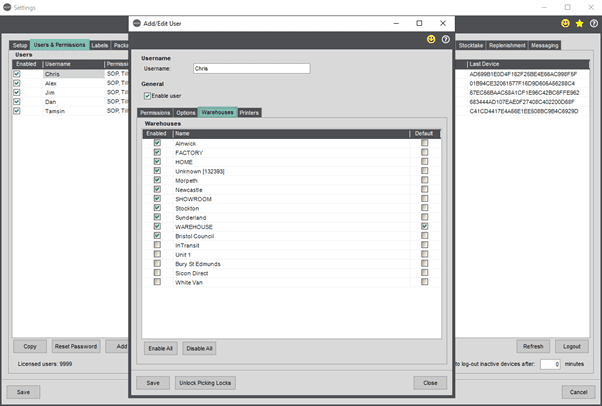

When a user is added or edited, the follow screen opens.

![]()

Within the permission screen, access to handheld tasks is controlled, the standard Sage ‘Core’ tasks and Sicon add on modules ‘Extensions’. This controls the menu options that are available to the user in the handheld.

![]()

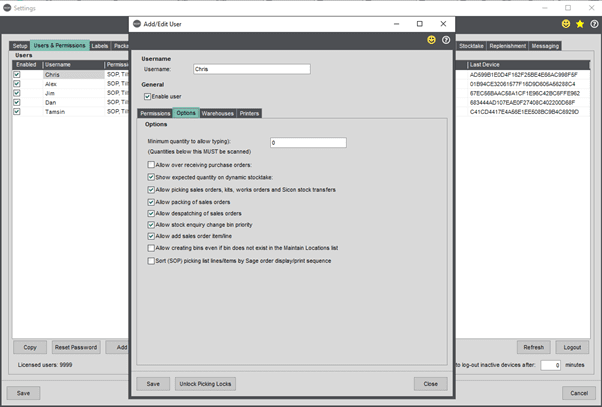

Within the options tab, additional user permissions can be set. The quantity of units that a user can manually enter rather than scan can be set here. Users can also be set to be able to over receive stock on purchase orders. The ability to show the expected quantity on dynamic stock takes for the user can be set, this shows on the right hand side of the dynamic stock take screen.

![]()

The allow picking sales orders, kits, works orders and Sicon stock transfers, allows users to pick items with these options in the handheld.

The allow packing and despatching tick options dictates what processes the user can perform within a sales order on the handheld.

The allow stock enquiry change bin priority allows bin priorities to be changed in the stock enquiry screen.

The allow add sales order item/line allows lines/items to be added to a sales order in the handheld.

The allow creating bins even if bin does not exist in the Maintain Location list – allows users to add bins that have not been defined in the maintain locations screen – caution needs to be taken if this setting is turned on as the bins created may not have the desired bin priority and duplicate bins with different text cases (capital and lower case) can be created.

The Sort (SOP) picking list lines/items by Sage order display/print sequence will set the order of lines on the handheld to match that in Sage. There is also a SOP global setting for this.

The unlock picking locks, removes any rogue picking locks on SOPs. The picking locks are being used to identify that the sales order is being picked by a user. This shows in the Sage sales order.

![]()

And also on the handheld.

![]()

![]()

In the warehouse tab, access to warehouses for the user can be set. A default warehouse can also be selected. These will dictate what warehouses the handheld user can log into on the device.

![]()

In the printers tab, printers can also set up against the users, this overrides the default printers, the printer set against the report or that selected against the warehouse. These can also be set from within the application.

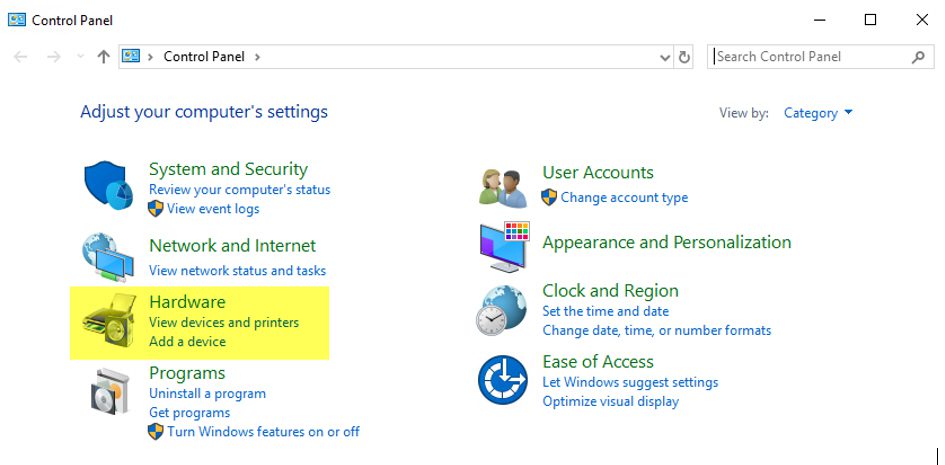

6.3. Labels

![]()

A default label printer can be set from a list of printers available on the Sage server. These printers need to be installed on the server and to be available to the SiconWebAPI user. Log onto the server as the Siconwebapi user and install the printer driver for the required printers to be available.

Specific label definitions can be designed that can be used to generate labels from within the handheld, printing a target report. There are standard definitions, that can be used from transactions on the handheld e.g. PO receipt. You can also create custom label definitions for example a particular customer may want their preferred labels on despatched products.

![]()

![]()

There is also the option to create custom package labels and package content labels that can be different for each package type, e.g. boxes and pallets.

![]()

The criteria fields shown on the standard labels, show which fields are required in the Sage report for the label to print.

The print labels button at the bottom of the label setting screen, allows labels to test printed from within Sage, printing an ad hoc label.

![]()

The despatch note tab, can be used to troubleshoot when printing despatch notes from the device is not working. Put in the correct criteria and click on run checks to be given the results.

![]()

6.4. Packaging

The format prefix and number of the packaging units can be set in this screen.

![]()

For pallets a GS1 SSCC format can used. Once the option is ticked, the extension digit, company prefix and serial number can be entered.

![]()

When the system creates a SSCC label using this format a check digit is added to the end of the number to create an 18 digit length number. For example when a pallet number is auto generated in SOP picking/packing.

![]()

When the option to use GS1 SSCC format for all packages is set, the system will use the SSCC set for all package types.

![]()

For example, in a SOP the box number will be based on the SSCC number.

![]()

The option to make picking into a tote compulsory, ensures only totes can be selected in SOP processing.

If a tote is not selected before picking in a sales order, the following message is returned.

![]()

The option to confirm packaging when moving stock controls whether package details need to be added when moving stock via standard Sage stock movements.

![]()

With the option set as yes, match quantity- if stock is added, then the package record also needs to be added. If the setting is set yes, with warning, no package needs to be set but a warning will be shown.

![]()

Any existing packages for the stock item in the location will show. Clicking on add package allows a new package record to be created and linked to the stock being added.

![]()

The package number, can be entered, along with the batch number if required and the quantity for the package.

Clicking on okay will add the stock and the package item.

![]()

The following Sage stock movements will ask for the package when the setting is set to confirm the package: return to supplier, internal issue, customer FOC issue, return from supplier, internal return, write off stock, add stock, transfer stock, SOP amend despatch, SOP confirm return, SOP amend return.

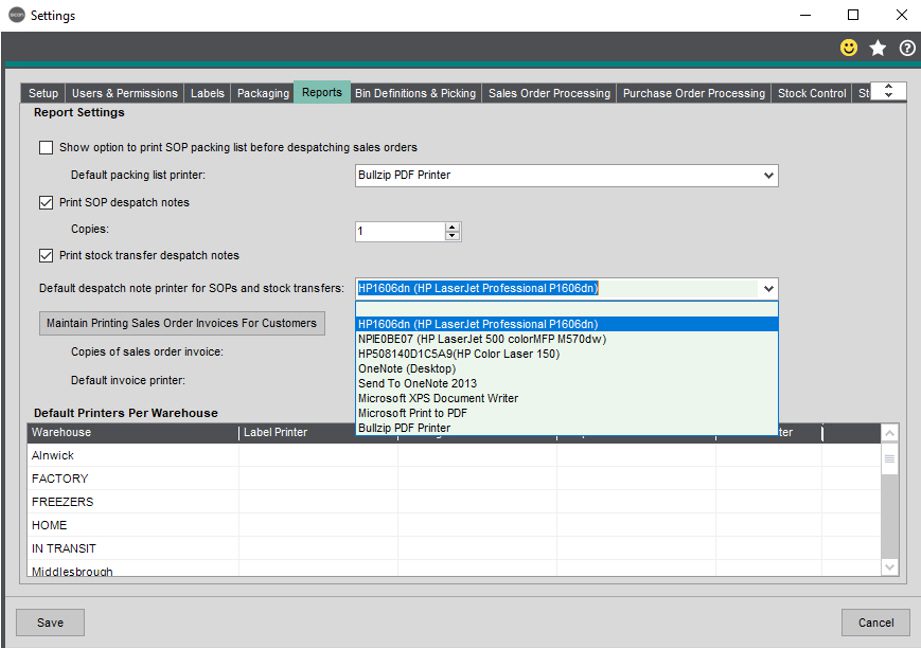

6.5. Reports

![]()

You can enable a packing list report to be printed during SOP processing and specify the printer to use.

The printer to be used for printing despatch notes and the copy quantity is configured here.

You can also set that a stock transfer despatch note needs to be printed when processing the Sicon stock shortage transfer.

The option to maintain sales order invoices for customers, opens a window where customer invoice printing options can be maintained.

![]()

You can also state that a sales order invoice can be printed during SOP despatch and which printer to use and how many copies to print.

You can also set different printers per warehouse.

6.6. Bin Definitions & Picking

![]()

Bin definitions allow different types of bins to be created based on the Sage allocation priority set against the bin. The bin type allows the order of allocation and picking to be set and also defines different bin types, such as bulk or pick face.

Prevent picking from put away, returns, bulk bins and inspection bins prevents users from picking stock items on SOP, works orders or kits on the handheld. Note users will be able to pick the stock within Sage. This restriction does not prevent allocation it is purely for picking.

There is a warning message on the sales order when stock is allocated to a restricted bin.

![]()

![]()

There is also a message in the works order pick screen and kit pick screens.

![]()

Cleanup:

Delete empty bins: Clicking on this opens a new window where users can choose which empty bins to delete by bin priority. NB the cleanup routine will allow bins to be deleted based on the standard Sage ability. Where traceable items are being used, bins that have used to despatch/receive traceable items on sales orders/returns are not deleted. This is to avoid the issue of reprinting some documents that may result in lost traceable information if the bins are deleted.

![]()

If the Sicon Pick Bin is selected the system will check for any temporary pick bins with a ‘:’ in and remove them if the confirmed and unconfirmed quantities are zero and any corresponding linked SOPs have been invoiced.

Move free stock in pick bins to put away bin: This will move all free stock in temporary picked/packed bins to the put away bin. If the free stock cannot be moved a warning will be displayed.

![]()

When a picked/packed sales order line is cancelled/deleted, the stock movement will show as an AutoMovePicked. The stock is moved to the bin set as the PO putaway bin (normally Goodsin).

![]()

When sales orders are picked in the handheld, the system moves the stock to the Picked:SOP bin. Once picked on the handheld, the quantity on the sales order in Sage cannot be amended below the picked qty.

![]()

If the quantity needs to be reduced, it should be adjusted in the handheld, via the put back option.

When a sales order is part picked, the quantity can be adjusted in Sage.

For traceable items, with the Sage stock setting to select batches at allocation, the quantity field can be reduced down to the picked quantity, and the system will prompt the user to amend the batches. This allows the user to amend the stock that is not in the picked:SOP. In the example below, 10 were allocated on the SOP and 5 picked on the handheld, the Sage user can adjust the qty to 5 and select the batch in the Picked:SOP to stay allocated.

![]()

For non-traceable items or for traceable items where the system is set to select batches at despatch. The quantity field is greyed out for picked lines.

![]()

To reduce the quantity, use the reduce allocation button, the stock in the correct bin can then be selected to reduce down. In the example below, 10 were allocated on the sales order and 5 were picked, the Sage user can adjust the allocated qty to 5.

![]()

As the allocated quantity is now less than the order quantity, the order quantity can then be amended down to the picked qty if required , so in the example below the order quantity can be amended down to 5.

![]()

For lines where batches are selected at allocation, and the lines are part picked e.g. in the below example 3 out of the 5 allocated items have been picked.

![]()

If the reduce allocation button is used and the quantity changed, the following pop up will be displayed.

![]()

The correct batches to reduce down can be selected from the amend batch/serial button on the sales order.

![]()

![]()

For lines where the picked qty is less than the quantity on the sales order line due to part allocated lines, the quantity can be reduced down to the picked quantity. In the example below, the sales order line qty is 10, 5 are allocated and have been picked. The quantity field can be amended down to the picked qty of 5.

![]()

Enable Smart Picking:

When smart picking is enabled the picking order of bins is reversed, so that the picking priority will be from priority 9 bins down to 1. This setting can be used to prevent users being sent to bulk bins to pick stock. The allocations are made to the bulk bin to keep free stock in the pick face bin.

![]()

On a sales order the system will allocate to stock in the bin priority 1 to 9. For example the below sales order is allocated to the bulk (priority 1)

![]()

On the device, it is asking to pick from the pickface bin, even though the sales order line is allocated to the bulk bin.

![]()

On the stock item, there is stock available in both bins:

![]()

When the item is picked on the device the system amends the allocation record from the bulk bin to the pickface bin and then to the picked:SOP bin.

![]()

N.B. When the Sage setting to select batches at allocation is on, Smart picking will not override the allocated bin location for the traceable item. So if batch stock is stored in both bulk and pickface bins, and stock is allocated to the bulk bin, the user will be sent to the bulk bin (smart picking logic is supressed). It is therefore not suggested to use Smart picking when selecting batches at allocation.

The setting to ignore inner carton quantities when assigning pick locations, will disregard any quantity set on the inner carton quantity, which can influence the bin the picker is sent to pick the stock. See the notes on the Sicon stock Barcoding tab settings below for further information.

The setting to assign stock from bin with full allocated stock quantity available will impact on which bin the users is set to for picking. The system will try to send the picker to a single bin to meet the sales order line demand.

For example, the following stock code is in multiple bins

![]()

If a sales order is raised for say 35, and the system is set to select batches at despatch, the handheld will send the user to bin C-A-01 as this can fulfil the line in full, even though the allocation is to the bulk bin.

![]()

![]()

The setting to disable smart picking for stock shortage transfers, allows smart picking logic to be supressed for stock transfers. This can be used where the stock transfer import has been used and specific bins to pick from have been selected.

The setting to use stock item sales order fulfilment sequence – can be used to ensure the Sage fulfilment settings work as expected.

In the example below, there are batches with different sell by dates in different bins.

![]()

With the setting on, when a sales order is allocated, the stock will be allocated on the smart picking bin logic. So in this example, the stock is allocated to the Bulk bin with the lowest bin priority.

![]()

![]()

On the handheld, the picker is sent to the D-A-01 bin as this contains the oldest batch (Nov23) and the stock fulfilment setting is set to pick by oldest sell by date.

![]()

The setting can be used with all the stock fulfilment sequences, for FIFO we are using the traceable receipt date of the stock item.

![]()

The setting to pick oldest first for sales order, then by bin definition, influences which bin is shown in the handheld on a sales order line based on the stock received date.

When stock is received in the handheld, via POP or add stock, the system writes the date the stock is received to a new sql table. This record is then looked at to dictate which is the oldest stock to pick and will amend the bin shown on the device accordingly.

This setting only works with smart picking enabled. When the setting is turned on, the system will treat the existing stock as the oldest stock and will be picked first, new stock will be given dates as it comes in.

The option to always pick from Returns, Inspection, Put Away or Default Pick Face bin before oldest, means that stock will be picked from these bins in preference to older stock in the Bulk bin.

6.7. SOP Settings

General SOP settings:

![]()

The ‘Receive SOP Returns into bin’ setting dictates what bin sales order returns go to when processing in the handheld.

Add packing stage to sales order despatching: An additional stage in the SOP processing for packing orders can be created.

![]()

Once the item has been picked, a packing list can be printed and it can then be packed.

![]()

The stock is moved to a SOP:Packed Bin

![]()

The sales order can then be despatched from the packed bin.

![]()

Allow despatch of all picked items without confirming counts or serials – This allows all items that have been picked to be easily despatched in the handheld. In the picked window, click on the action button, the user can choose to despatch all picked items.

![]()

Allow despatching all sales order on a wave- allows sales order to be despatched from the wave pick screen on the handheld.

![]()

![]()

Disable despatch sales orders create a wave prompt – With this enabled the prompt for a user to be asked to create a wave on the handheld (see below) is supressed. This is also supressed if the user does not have access to wave picking.

![]()

Allow scanning sales orders that are not allocated when selecting a sales order to pick. With this setting on, unallocated sales order (that do not show in the sales order list in the handheld) can be selected by scanning a barcode for the sales order number. The barcode can be added to say a paper SOP document.

![]()

Scanning this barcode loads up the sales order.

![]()

You can then pick the lines by scanning/tapping the stock item and selecting the batch if required.

![]()

As the lines have not been allocated in Sage, the bin needs to be scanned to confirm where the stock is being selected from.

![]()

![]()

The option to allow sales orders to be allocated on the device allows sales orders to be allocated from the device. After scanning a barcode for an unallocated sales order, the user will be asked if the order should be allocated. Stating yes to this message will then allocate the order based on the Sage allocation rules.

![]()

The order then opens and can be picked/processed.

![]()

Allow stock items to be scanned first when picking- This allows the stock item to be scanned first during picking instead of the bin, the bin then needs to be scanned to confirm the pick. The auto select first expected bin (do not require bin scan) setting, will populate the expected bin once the product barcode has been scanned.

Automatically complete pick when scanning the last required item i.e. do not require pressing of the “Confirm” button. When you pick the last quantity of a SOP detail line, the system will auto confirm the pick.

Auto set the pick quantity to the required quantity when an item is selected (for traceable items only- this is so that the user will go straight to selecting traceable items). With this setting on, the user will not have to enter the qty on a SOP line for traceable items, they will just need to select the serial numbers. If batch numbers are being used, if the batch number is scanned then the full qty of the batch will also be set.

![]()

Enable cached picking.

With this enabled, sales orders will be grouped together and stored to speed up performance in the handheld. The 1st time an order is loaded in the handheld the list is stored, with each pick/pack the list does not need to be loaded again, which speeds up picking/packing.

When smart picking is enabled, it also does a soft allocation on the stock in the bin that is suggested on the handheld. This is used to prevent multiple pickers being sent to the same pick bin location to pick the stock which could cause stock out issues. When the system decides on the bin to send the picker to, any existing cache lists will be taken into account and the subsequent pickers may be sent to different bins to where the apparent free stock is located.

Lock sales orders while picking on handheld device (except Wave Pick)- with this setting on, the sales order can not be amended in Sage, when the sales order is open in the handheld.

![]()

The sales order can also not be despatched in Sage.

![]()

Lock sales order pick/despatch selection while amending in Sage (except wave pick). With this setting on, if a Sage user is amending the sales order the handheld user can not access the order on the device.

![]()

Restrict multiple users from selecting the same sales order on hand held devices- This prevents multiple users picking the same sales order.

![]()

Show County Code on SOP List – The country code from the customer trading tab is shown on the handheld.

![]()

Ready to Pick Settings:

![]()

The ‘Ready to Pick’ settings allows the ready to pick flag to be used within sales orders to dictate what sales orders appear in the handhelds. This can be automatically set when all lines are allocated or when a pick list is printed. It can also be automatically unset on partial despatch.

![]()

The ready to pick flag has been included in the sales order list accessed from within the barcoding module.

![]()

Advanced Settings

![]()

Allow picking by zones for sales order processing: With this set, handheld users can then select zones they are working in and then pick sales order lines based on these zones.

![]()

![]()

Of the 4 lines on the sales order, only the 2 lines in zones C and D appear for the user to pick.

![]()

![]()

Any lines on the sales order that are already picked will appear for packing/despatching. There is no zone restriction on the SOP:picked or SOP:packed bin

The zone picking also works on the wave pick screen

![]()

Once the wave is selected only lines that are in the zones selected appear for picking.

![]()

The enable move to button on sales order despatch setting allows users to move the picked items to a specified bin location within a sales order e.g. a packing despatch bin location. In the picked window, click on the action button, the user can choose to move the items to a new bin.

![]()

Additional picked items can be moved into the same bin or a new bin.

![]()

![]()

The moved items can then despatched.

Enter number of boxes at despatch – allows the number of boxes to be entered at despatch. This is stored in a sql table and can be used for courier integration, the number of courier labels will be dictated by the number of boxes set. With this setting on, the ability to print box labels and put items into boxes from the SOP screen is suppressed.

![]()

Disable prompt for package dimension requirements. With this setting ticked the handheld user is not prompted to the enter the box dimensions when using packages on the device.

![]()

Hide Info tab on sales order despatch – With this setting on, the info tab within the sales order despatch screen in the handheld is removed.

Hide sales orders on handhelds if the sales ledger account is on hold. With this setting enabled, if the customer account is on hold, see below, the sales orders will no longer appear in the handheld. This is in addition to sales order on hold being hidden on the SOP list.

![]()

Prompt user for package during sales order- With this setting on, when a handheld user selects a sales order from the sales order list in the handheld, they will then be prompted to select a packaging item.

![]()

Once the packaging item is created the system will then use this when picking the sales order.

![]()

Sort picking list lines/items by Sage order display/print sequence- With this setting on, the sales order line in the handheld will be displayed based on the print sequence rather than the bin pick sequence.

![]()

![]()

Use sales order promised for date for the despatch date and invoice date (if invoice printing via handhelds is turned on). With this setting on, and when the report setting to print an invoice during SOP processing has been set, see below, the despatch and invoice date will use the SOP promised header date.

![]()

So, in the example below, the sales order was despatched on the device on the 22nd April 2021, but the despatch date has used the promised for date of 24th April 2021.

![]()

The setting to use SOP despatch label instead of Ad hoc label when printing labels during picking sales order lines, allows SOP labels to be used instead of the Ad hoc label.

Prompt the user to confirm if a bin is empty after picking: With the setting on, if a sales order pick results in the pick bin becoming empty, then the user will be prompted to confirm if the bin is actually empty.

![]()

The result then gets recorded in the warehouse notifications in Sage.

![]()

Enable despatch packages option: with this set there is a new option during SOP processing to despatch the package. This setting allows packages to be despatched before the sales order is fully despatched, so can be used where boxes need to be picked and despatched as they are completed.

![]()

![]()

The package can be selected and the action button then gives options to print the package label or packing lists. When the Sicon courier is installed, the option to change the courier is shown. The package can be despatched and a courier label created.

![]()

Enable ‘Distribution Order’ option – with this ticked, a field on the sales order becomes available to flag the sales order as a distribution order. With this ticked there is then a new field on the sales order line to enter a store id.

![]()

![]()

The store ID and associated store can be maintained in the maintain stores section within the barcoding maintenance window.

![]()

In the below example, each line has been linked to a different store ID.

![]()

When picking this order on the device, the user is then prompted to select the store ID they want to pick for.

![]()

Once a store has been selected, only the sales order line(s) that relates to the store to pick are displayed.

![]()

Set ‘Quantity to Despatch’ to picked quantity when despatching in Sage. With this setting on, after picking a sales order on the handheld, the qty to despatch is preset as the picked qty. In the example below some of the lines have been picked on the handheld.

![]()

When despatching in Sage, these picked quantities are used to set the qty to despatch.

![]()

Where lines are part picked, the system will despatch stock from the Picked:SOP bin. For traceable stock, the batches need to be confirmed if selecting batches at despatch.

Van Picking:

![]()

The analysis codes for van identification and drop number dictate which sales order analysis codes to use.

Add packing stage to zone packer adds the packaging stage to the zone packer screen.

6.8. POP Settings

![]()

Receive PO’s into bin- The bin selected here will be used during the PO receive process and the putaway process.

Items requiring inspection go to bin – This bin is used for the inspection process.

With the setting to disable the ‘Due this week/overdue’ flag in receive purchase orders, all future purchase orders will appear.

Allow receipt directly into specified bin (to skip PutAway) – With this setting on, in the action button during PO receiving, you then have the option to put the stock directly into a bin.

![]()

Allow label printing during the put away process, enables the labels to be printed during the put away process, using the ad hoc label definition.

![]()

When receiving batch items, always add to existing batch if the same batch already exists- this setting dictates whether an item should be added to the existing batch or create a new batch. If separate batches are required, then the stock item also needs to be set to allow duplicates. In the below example, we have created 2 batches for the same batch number.

![]()

Inspections:

Prompt user to select failed inspection items warehouse and bin location. With this option ticked, when failing an inspection on the device, the user can select a warehouse and bin to move the failed stock to.

![]()

With this unselected the warehouse and bin options below will be used.

Warehouse for failed inspected items – specifies the Warehouse to put failed inspected items.

Bin for failed inspected items – specifies the Bin to put in failed inspected items.

If quantity received does not match quantity expected when receiving a purchase order line, then flag items as requiring inspection – the stock will be received into the bin for items to be inspected.

6.9. Stock Control

![]()

With the first stock setting ticked the handheld will prevent a stock item being put into a bin that already contains a different stock item.

![]()

With the second setting set, when you come to pick serials numbers within the handheld on say a sales order or stock transfer the system lists out the available serials. There is also an option to select all serials. This setting only shows when the Sage stock setting to select serials at despatch is set.

![]()

Allow adding stock items barcodes when picking non traceable items, allows barcodes to scanned on the handheld and added to the stock item barcode in Sage.

![]()

The barcode gets added to the stock item and can be seen by clicking on the barcode button on the stock item.

![]()

Hide pick bins from bin selection dropdowns selection in Sage: With this ticked the temporary picked bins will not appear in bin selection dropdowns in Sage.

Include inactive stock items: When enabled, this setting allows Inactive stock to be added, via the handheld, through the ‘Add Stock’ and ‘Dynamic Stocktake’ functions.

If user had access to works orders, and adding a stock item that could be backflushed, default to always backflush instead of asking user what to do. This setting dictates what to do when adding a built stock item (via add stock) on the handheld (when Sicon works orders are installed).

![]()

With the setting on, the above message is not shown, the system creates and backflushes the work order.

The following setting, will default the unspecified bin, as the bin to use when adding stock or adding a sales order line.

When selecting stock item, default bin to ‘Unspecified’. (This is only for add stock and adding sales order lines at the moment).

![]()

The following setting can be used to enable serialise items to be treated as unassigned. Serial numbers with this prefix are treated as unassigned serial numbers.

![]()

Stock items that use this prefix can be booked into stock.

![]()

![]()

In Sage the serial numbers have been created.

![]()

However, in the handheld, when you move the stock such as in the putaway process, the system treats them as unassigned.

![]()

The serials can be assigned during SOP picking

![]()

![]()

To speed up the assigning of these serials a QR code containing multiple serials can be created, with the serials separeted by carriage returns. This can then be scanned when assigning the serials. The below QR cotains 5 serials numbers, A121 to A125.

![]()

The QR code can be scanned when assigning during SOP picking and all 5 serials will be asisigned with one scan.

![]()

![]()

This multi serial number barcode can also be used at goods in.

The custom barcode feature allows for non-standard barcodes to be defined, so that the Sicon barcode solution can identify the relevant parts of the barcode.

The handheld barcode scanning enforcement for bins and stock items: dictates whether a user has to scan a bin or stock item or tap on it to select it.

When the enforcement is set to encourage, the user gets the following message, if they do not scan the barcode.

![]()

If they select yes, they are then prompted to put in a reason.

![]()

The reason is recorded in the warehouse notifications section in Sage.

![]()

With the setting to be enforced, the user has to scan the barcode of the stock item or bin.

![]()

Once the stock item barcode has been scanned, the quantity can then be manually adjusted (without scanning).

The ignore scanning enforcement on goods received and sales returns, will discard the enforcement required when receiving a purchase order or sales order return.

Allow sequential serial handling with first and last entry only. This allows the first and last serial numbers to be scanned or entered during add stock or receiving a purchase order. Tapping on the screen then gives an option for the system to auto populate the serial numbers in between the serials scanned.

![]()

![]()

![]()

Configurable description- allows an additional stock description to be generated from stock analysis codes or the manufacturer part number for all stock items.

![]()

Selecting the fields and then saving, creates the new description for each stock item.

![]()

The description can be seen on the stock item in the Sicon tab.

![]()

It has been populated from the corresponding analysis data or manufacturer part number.

![]()

On the handheld the configurable description is added to the stock name, so appears on multiple screens. E.g. stock enquiry and Put Away.

![]()

Where the option to include the analysis name is set, the stock analysis name is added to the configurable description and shows on the handheld.

![]()

Stock Transactions Analysis Codes:

![]()

On this screen, analysis codes set up for stock transactions, can be linked for use with the inspection process on the handheld.

![]()

On the handheld after inspecting the item, the user is prompted to populate the inspection analysis codes.

![]()

The values are stored in the stock history on the stock item.

![]()

They are also saved in the warehouse notifications within Sage.

![]()

6.10. Stock Transfer

![]()

The stock transfer tab in the settings allows the configuration of stock transfers between warehouses.

The last transfer number is used to generate the next stock transfer sequence number. You can set the default origin and transit warehouses. It is important that an in-transit is selected here rather than a standard warehouse as the warehouse set here is hidden within the standard Sage stock transfer screen.

You can set the internal area, which then dictates nominal postings. You can also enable courier and delivery code selection and maintain the lists of these. The enable bin selection, allows the bins to be selected during the creation of the stock transfer.

Set the default ‘’To Bin” to the highest priority bin (excluding priority 1), this will dictate which bin to default into the ‘To bin’ when creating a stock transfer. In the screen shot below, the bin C-A-01 has been defaulted in as this has a bin priority of 2

![]()

![]()

The internal area to use when auto issue items on receipt, dictates which internal area to use when stock items are auto issued when receiving a stock transfer. This requires the stock item to be set to auto issue on receipt.

The ready to pick flag settings, control when the ready to pick is set on the stock transfer

- When printing the picking list

- When all lines are allocated

- Manually

The setting to ask for signature at despatch controls whether a signature is required when despatching a stock transfer.

The ‘hide the add new lines to pick option when creating new stock transfers on the device’ setting, will set lines that have been added on to a stock transfer on device to be picked.

For example, in the transfer below

![]()

A bin and stock item are scanned

![]()

Clicking on the action button, sets the item to be picked

![]()

With this setting off, the item would be added to the transfer, but would then need to picked.

With this setting on ‘Single stock transfer, set required quantity to current free/allocated total if batch is scanned’, when a complex barcode containing a batch is scanned on a single item transfer, the full batch quantity is set.

For example scanning this barcode, will set the transfer quantity to the full quantity of the batch in the bin, in this case 5.

![]()

![]()

The lock stock transfers setting, prevents the transfer from being processed in the handheld if a Sage user is editing the transfer.

![]()

If a handheld user is processing the transfer on the device, then it cannot be edited in Sage.

![]()

6.11. Stocktake

![]()

Write off category: This is used to dictate the nominal postings when stock is removed by the Sicon dynamic stock take. When adding stock, the issues nominal set against the stock item is used.

Tolerance: A tolerance can be set to prevent users in the handheld processing transactions that are above this tolerance level.

![]()

The traceable adjustments internal area, will set the internal area to be used on a Sage stock take when processing traceable items.

![]()

Stock take per batch: When performing a dynamic stock on the device, each batch will show on the stock take screen for counting.

![]()

This allows each individual batch to be counted separately in the bin.

![]()

Allow ‘found stock’ to be moved from ‘expected bin’ during count – With this setting on during a dynamic stock take on a batch item, if a batch is found in a bin that already exists in another bin, the user will be prompted to move the batch to the found bin.

![]()

The system will move the full expected qty from the original bin, once the new qty is confirmed then any adjustments will be made.

![]()

6.12. Replenishment

![]()

Replenishment stock requirement for: The number of days populated in this screen dictates what allocations the system will attempt to move when performing a replenishment movement.

Replenish when level reaches minimum/reorder- You can decide on whether to replenish stock based on the minimum or reorder level set against the bin.

Replenish from ‘Overflow’ bins will make replenishment suggestions to try to replenish from overflow bins.

Replenish from ‘Other’ bins will make replenishment suggestions to try to replenish from other bins.

Replenish future demand quantities- Will consider future sales order in the quantity to replenish

See the handheld features on replenishment below for examples

6.13. Messaging

Allows developers to hook into a message service in the web api at the point of pick, pack and despatch. E.g. to allow printing of courier labels. When the Sicon courier module is installed, the despatch option needs to be ticked.

![]()

6.14. Settings on the Stock Item relevant to Barcoding

![]()

Barcode: with this populated the handheld will recognise the barcode based on this barcode field. If this is blank, then the stock code will be used instead.

Barcodes button

![]()

Additional barcodes can be linked to the stock item within the barcodes button. These can also be associated with a supplier, so will also appear on the supplier barcode tab. These barcodes can be associated from handheld at goods in or from the stock enquiry screen.

![]()

Inspection required when receiving purchase order: When you bring this stock item in on a purchase order, the inspection symbol appears.

![]()

When you receive in the stock it is put to the inspection required bin set in settings e.g. inspecitonreq bin. When putting this stock away, the system will move the stock from the inspectionreq bin to an inspection bin. See further notes below on the inspection process.

![]()

![]()

The inspection required bin is created with a bin priority of 6 and the inspection bin with a priority of 7.

Sicon stock Barcoding tab settings:

![]()

Label required on goods received: With this setting on, in the PO on the handheld, the flag to state the item requires a label is defaulted on.

![]()

With the default ‘only print one label’ on goods received. The label quantity will show as one. You can also configure labels that are specfic to the stock item.

![]()

Unit of measure override on devices: This allows a unit to be selected to show on the handheld in the POP, SOP and transfer screens, even though the unit on the transaction may be in a different unit.

On the example below, the stock unit is Sq metre, but handheld users pick in boxes.

![]()

![]()

If a sales order is put on to sell the stock in Sq metres, the handheld will show this in boxes using the unit of measaure to convert the Sq metres to boxes.

![]()

On the handhled the user is asked to pick 4 boxes. Once processed in the handheld, the system updates the stock history records in Sage in the stock unit.

![]()

Ignore quantity when scanning complex (GS1-128) bacode: With this setting, on the quantity stored in a complex barocde (identifier 30) will be ignored when scanning the barcode, the quantity will be uplift by 1 only.

Inner carton quantity/Outer carton quantity: These can be populated in order to direct the handheld user to either the Pickface, or Bulk bins for a single stock item, depending on the quantity required. Quantities divisable by each carton quantity will be used to decide whether an Outer, Inner or ‘Each’ is required. Please note, this is only available when Smart Picking is enabled.

Example

Inner Carton Qty 0

Outer Carton Qty 50

![]()

Stock Balances

Pick Face bin 100

Bulk 995

Order Quantity 330

Pick Allocation

Pick Face 30 (each)

Bulk 300 (6 x outer)

![]()

The handheld has stated for the picker to pick 30 from the pick face bin as this is less than 50 and then to pick the remaining items from the bulk bin (in packs of 50).

Where both the inner and outer carton quantity are set, then the inner caton quantity will be used.

If the outer carton quantity is less than the inner carton, then the outer carton quantity is used.

If the setting to ignore inner cartons is set, then the system doesn’t use inner cartons, only the outer carton quantities.

The usual pallet in stock unit is used by the system to know how many stock units make up a pallet. For example when adding stock on the handheld, if the stock item is scanned and then a pallet label scanned, the system will populate the qty based on the pallet qty.

![]()

![]()

The usual pallet quanity in box unit has been created to dictate how many box units fit on a pallet- currently this is not being used.

SOP picking priority overides – when poulated this will impack on the sort order of the sales order lines in the handheld. With nothing populated in these fields a sales order sequence will be sorted based on the bin picking sequence set up in the maintain locations screen

![]()

So in the SOP example below, the lines have been re-arranged in the handheld based on this sequence

![]()

![]()

If a value is put against the stock item then this will overide this sequence.

![]()

![]()

The toaster is now at the top of the SOP list. The list is sorted first on field one and then field two, so if values are put in the acs/mixer as follows, this will then appear at the top of the list.

![]()

![]()

Enable catch weight, with this setting if this stock items is put on a sales order, the qty picked on the order can be greater that the qty specified on the order. The sales order line quantity is updated to reflected the picked quantity. In version 20 we moved the catch weigh setting from a global setting to be product specific. This setting is only available when the Sage stock setting to select serials at despatch is set.

The weigh scales icon show for the stock item in the handheld to highlight the item is catchweighted.

![]()

When picking on sales order / works order waves, don’t group the lines: With the setting on when multipe sales/works order lines are put onto a wave for the same stock item, when the user comes to pick the line, each sales/works order will show the individual order. In the example below, for the acs/expresso from two sales orders on the main ‘To Pick’ screen the sales order numbers do not show.

![]()

When you come to pick the lines, the sales order numbers then show.

![]()

Hold picking this item if on a sales order, with this setting on, the item will not appear on the sales order for picking.

Batch Weights enabled: With this setting on the, when stock is recieved via a purchase order or add stock in Sage the user is prompted to add in a weight.

![]()

![]()

The weights are visible from the amend batches screen in Sage and the view batches screen.

![]()

![]()

![]()

When a dynamic stock take is performed on the stock item, the weight icon can be selected and the weight entered.

![]()

![]()

The in stock quantity of the batch is adjusted based on the new weight.

![]()

The current weight is updated on the batch in Sage.

![]()

Configurable description – see notes above in the barcoding stock control settings on how to configure this.

Auto set the pick quantity to the required quantity when an item is selected. This is the same setting as that set within the SOP settings, but has been made stock item specific. With this setting on, the user will not have to enter the qty on a SOP line for traceable items, they will just need to select the serial numbers. If batch numbers are being used, if the batch number is scanned then the full qty of the batch will also be set.

Barcode Setting Enforcement: These options will overide the Encourage and Enforce settings, within the main Barcoding Settings, for this stock item only.

![]()

The label defintions will show any labels that have been configured for the stock item.

Locations:

![]()

In the locations tab of the stock item, the bins linked to the stock item can be viewed/amended. The bin definition details have been added. When adding a new bin in Sage, the allocation priority can be selected from the list.

Against the bins you can also specify the re-order, minimum and maximum quantities used for bin replenishment, see notes below.

![]()

Stock item Images

Images photographed on the handheld in the stock enquiry screen can be saved to to the Sicon stockitem images.

![]()

The images are saved within the Sage attachments folder.

![]()

Stock Transfer

![]()

The auto issue item when received setting will cause the stock item to be auto issued when a stock transfer is received.

6.15. Changes to View Item History Screen

In the stock item history screen, the handheld user that has processed the transaction shows against the barcode device. The user is the web api user set up for the barcoding system. This screen pulls the barcode user from the SiconWABhistory table- the Sage history table has not been updated with the handheld user.

![]()

6.16. Enable Module

Opens the enable module stings screen so manual strings can be entered.

![]()

7. Handheld Features

7.1. Logging in

To log into the app tap on the Sicon barcoding app.

![]()

Click on the server button, then scan the QR code from Sage setting screen to populate the server details and company number (these can be manually entered from the barcoding setting page in Sage if required).

![]()

The user name and password as set up in Sage can then be entered.

![]()

When the user has been set with a default warehouse, the user will then be logged into this warehouse.

![]()

Where there is no default warehouse set, the user will need to select the warehouse.

![]()

The features available in the handheld are controlled by the user permissions.

![]()

![]()

7.2. Receive Purchase Orders

In this screen, purchase orders that are ready to receive will show. You can decide to see orders due this week or to see all orders, by clicking on the due this week/overdue. You can also see/hide fully received orders, by clicking on the hide fully received orders.

![]()

When multi line purchase order have had some lines received, the following icon shows.

![]()

Orders can be searched for by the number, supplier details or by date.

![]()

Once an order is selected, the order details then show, the stock code, the POP part reference, stock item description, and requested line date (if populated).

![]()

The purchase order lines can be filtered by the line requested delivery date.

![]()

Product barcodes can be scanned to update the quantity to receive or quantities can be entered manually. Where items are traceable products the serial numbers also need to be scanned/entered.

![]()

If the stock item is set to require attributes the following icon will show, and tapping the icon will open the attribute entry screen. The attributes can be entered here, or when adding the batch information.

![]()

Once the items have been scanned/entered, the action button can be used to confirm the receipt, at this point a supplier GRN number is required. The stock can either be put to the putaway bin or direct to a chosen bin (assuming the PO setting to allow this has been ticked).

![]()

Where supplier barcodes are being used, if a barcode is scanned and the system does not match it, the system will prompt you to add the barcode to a supplier barcode.

![]()

![]()

The barcode is added to stock item supplier barcode field.

You can also print labels at this point using the action button, so that barcodes can be attached to the products when own barcodes are being used.

Where stock items are set to be traceable and the system auto-generates the number. When the stock is received the labels can then be printed with the serial/batch number created by Sage.

![]()

If the Sicon documents module is installed, then the user can also take a picture using the camera icon at the goods receive stage of say the delivery note. The image is saved against the goods receipt within Sage.

![]()

![]()

7.3. Receive Container

If the Sicon Distribution module has been installed, and container management is enabled, the option to Receive Containers will show on the handheld.

Please note: The Purchase Order supplier must be listed on the Stock Item, Suppliers tab, in order for the item to be displayed on the handheld device.

A list of containers is displayed.

![]()

Either scan or tap on the container number required.

With the ‘Show all expected supplier container items’ button on, all container items for a specific Supplier will be displayed.

![]()

With this button disabled, each item will appear as it’s scanned.

![]()